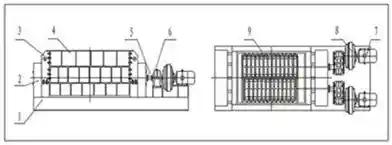

1.Foundation 2.Bearing Seat 3.Lifting hole 4.Inlet 5.Coupling 6.Reducer 7.Motor 8.Hydraulic Coupling 9.Teethed Roller

Double-toothed roller crusher (Cutting coke machine)is suitable for medium and coarse crushing of hard,medium and soft materials with compressive strength less than 240MPA and less than 30%moisture,such as various ores,coal,coke, petroleum coke,quickime,siica,carbon Solid materials such as FRP,FRP,asphalt chemical principle,etc.or equivalent to the above hardness.The equipment has the characteristics of low maintenance cost,reliable performance,less dust and bw noise.

Double teethed roler crusher(Cutting coke machine)is equipped with two teethed rollers.The roller surface is divided into wolf teeth,ring teeth,straight strip tooth,big board teeth and others.The maximum feeding size is 1200mm,the range of the discharge is 10-300mm.It is operated in the intermediate and coarse cnushing which has few powder and bts of grains.

It is suitable for mining industry breaks al kinds of ore steel industry breaking limestone,coke;thermal power plants,coking plant crushing coal;breaking raw coal of coal mine;petroleum coke breaking in coal chemical industry,electronics industry breaking slica;carbon industry crushing carbon block,solar industry breaking waste glass;concrete industry crushing lime and asphalt or in the similar occasions.

Working principle

Double teethed roler cnusher (Cutting coke machineiis equipped with two wear-resistant aloy rollers.Their relative rotation generates high extrusion pressure which crushes the material.The material is fed into the space between the two rollers, suffered both extrusion and shear

force.In the crowd rolling,cutting and grinding,then it is crushed into the required size and then sent by the transport equipment

2PG Series Double Teethed Roller Crusher(Cutting Coke Machine)

| No. | Specification | Feed size (cmn】 | Discharge size ((eSemm) | Production capacity(t/n | Motor Power (Kg |

| 1 | 2PG-10CT | <120 | 10-50 | 2-20 | 3×2 |

| 2 | 2PG-30CT | <120 | 10-50 | 6-40 | 5.5×2 |

| 3 | 2PG-50CT | <200 | 10-60 | 10-80 | 15×2 |

| 4 | 2PG-60CT | <300 | 10-80 | 20-150 | 18.5×2 |

| 5 | 2PG-80CT(Y) | <400 | 10-100 | 30-200 | 30×2 |

| 6 | 2PG-100CT(Y) | <300 | 10-90 | 40-280 | 37×2 |

| 7 | 2PG-120CT(Y) | <400 | 10-120 | 50-350 | 45 ×2 |

| 8 | 2PG-150CT(Y) | <600 | 10-150 | 65-450 | 55×2 |

| 9 | 2PG-220CT(Y) | <800 | 10-180 | 80-600 | 75×2 |

| 10 | 2PG-350CT(Y) | <900 | 10-200 | 90-800 | 110×2 |

| 11 | 2PG-50DCT(Y) | <1200 | 20-300 | 200-2500 | 160×2 |

| 12 | 2PG-800CT(Y) | <1200 | 20-300 | 300-3500 | 200×2 |

| 13 | 2PG-1200CT(Y) | <1200 | 20-300 | 400-5000 | 370×2 |