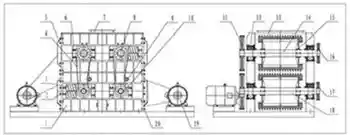

1.Frame 2.Prolection Bolt 3.Spring 4.V-belt 5.Observation Window6.Adjusting Bolt 7.Inlet 8.Upper Roll-Driven Wheel 9.Tensioner 10.Lower Roll-Driven Wheel 11.Upper Roll-Driving wheel12.Bearing Seat 13.Teethed roller 14.Upper roll-Main shaft15.Wheel hub 16.Upper Roll-Dnven Wheel 17.Lower Roll-Driven Wheel 18.Lower roll-Main shaft 19.Motor 20.Joint bolt

Introduction

Four teethed roller crusher is suitable for compression strength less than 240Mpa,water content less than 30%of the medium hard and soft materials.In addition,it is suitable for fine and intermediate crushing which has few powder and lots of grains.Such as coal,coke,fertilizer,raw material,petroleum coke,glass, chemicals and other solid materials.It has the characteristics of low maintenance cost,large crushing ratio, reliable performance,less dust and low noise.

The four teethed roller crusher is equipped with four crushing rolls,the upper two rolls are the tooth roll faces,and the lower two rolls are the stacking roll faces (flat roll face or straight tooth optional),suitable for feeding particle size less than 700mm,finished product size requirements 2-30mm medium and fine crushing operation.Such as electric heating plant fluidized bed boiler,ordinary boiler broken coal,chemical fertilizer plant broken fertilizer raw materials;copper industry broken frozen ore powder;solar industry broken waste glass tube;or similar to the above crushing occasions.

Working Principle

Four rollers crusher is fixed with four high-strength wear-resistant alloy grinding rollers.Their relatively rotation makes high extrusion pressure and shear force to crush the materials.Firstly the material is entered into the space between the top two rollers.It is extruded,rolled and sheared (rough broken) because of the rotation of the top two rollers.Then,it is secondly extruded and gnawing milled (fine crushing)by the middle two rollers which are relatively rotating.Finally,under the extrusion,cut and mill of the next two rollers,the material becomes the required size,then be sent out by the transport equipment.

4PG Series Four Teethed Roller Crusher

| No. | Specification | Feed size (en) | Dscharge size (asts5emn | Production capacityin) | Motor Power K |

| 1 | 4PG-4MCT | <120 | 2-20 | 6-50 | 11 |

| 2 | 4PG-50CT | <200 | 2-20 | 8-90 | 30 |

| 3 | 4PG-60CT | <200 | 2-3 | 15-150 | 37 |

| 4 | 4PG-80CT(Y) | <200 | 2-30 | 20-250 | 45 |

| 5 | 4PG-100CT(Y) | <200 | 2-30 | 30-380 | 55 |

| 6 | 4PG-120CT(Y) | <500 | 2-30 | 40-480 | 75 |

| 7 | 4PG-150CT(Y) | <700 | 2-30 | 65-640 | 90 |

| 8 | 4PG-220CT(Y) | <700 | 2-30 | 80-800 | 110 |

| 9 | 4PG-350CT(Y) | <700 | 2-30 | 100-1000 | 132 |