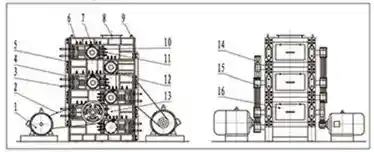

1.Motor 2.V-belt 3.Adjusting Bolt 4.Disc Spring 5.Plugging and Pressing Bolt 6.Upper slide fixing bolt 7.Oil cup 8.Inlet 9.Lifting hole 10.Pad connection bolt 11.Intermediate adjustment screw 12.Bearing Seat 13.Perspective window 14.Main Pulley 15.Secondary pulley 16.Observation window

Introduction

Six-roller five-stage crusher is suitable for superfine crushing of solid materials with compressive strength less than 240Mpa and water content less than 30%.such as coke,coal,ceramic raw materials,ore,water slag,gypsum.clay. salt,chemical raw materials,etc.The material has the characteristics of low maintenance cost.large crushing ratio. reliable performance,less dust and low noise.

The six-roller five-stage crusher is a patented product developed by our company (patent number:ZL 20131

0342587.X).The six roll faces are divided into a surfacing roll surface,a stud alloy roll surface or a flat roll surface.

The combination can be selected according to the user’s required particle size.and is suitable for superfine crushing operations with a feed size of less than 90 mm and a finished product size of 0.1-5 mm.Such as crushed quartz stone.

iron ore in the mining industry:broken feldspar in the ceramic industry;broken limestone in thermal power plants; broken water slag in cement plants;broken gypsum in building materials factory;broken chemical raw materials in chemical industry;or similar crushing occasions.

Working Principle

The six-roller five-stage crusher uses six high-strength wear-resistant alloy crushing rolls to crush the material with

high extrusion force and shear force generated by relative rotation.After the material enters the upper two rolls of

the V-shaped crushing chamber,it is subjected to the pressing force of the relative rotation of the upper two rolls.

After the first rolling and biting of the material (coarse crushing),then entering the relatively rotating second and third rolls of V-shaped After the crushing chamber enters the secondary extrusion and biting (fine crushing),after entering the third and fourth rolls of V-shaped crushing chamber for the third extrusion,after entering the four-and five-roll

V-shaped crushing chamber for the fourth squeeze rolling,Finally,the fifth and sixth rolls of V-shaped crushing chamber are subjected to the fifth crushing shearing and biting(superfine crushing)and then broken into the required particle size to be discharged from the outlet.

6PGS Series Six Rollers Five-stage Crusher

| No: | Specification | Feed size (m) | Dsdherge sze (atsteremm) | Production capacity | Motor Power (R) | |

| 1 | 6PGS-ImPT | <20 | 0.1-5 | 2-30 | 11(15) | 22(30) |

| 4 | 6PGS-60PT(Y | <60 | 0.1-5 | 12-120 | 37(45) | 45(55) |

| 5 | 6PGS-80PT(Y) | <60 | 0.1-5 | 20-180 | 45(55) | 55(75) |

| 6 | 6PGS-100PT(Y | <80 | 0.1-5 | 30-220 | 55(75) | 75(90) |

| 7 | 6PGS-120PT(Y) | <90 | 0.1-5 | 45-320 | 75(90) | 90(110) |

| 8 | 6PGS-150PT(Y) | <90 | 0.1-5 | 55-400 | 90(110) | 110(132) |

| 9 | 6PGS-180PT(Y) | <90 | 0.1-5 | 70-500 | 110(132) | 132(160) |