Introduction

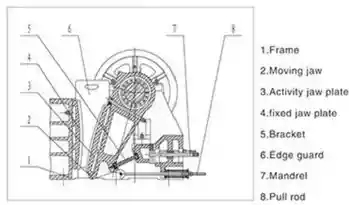

(Fine)Jaw crusher is used for crushing hard materials (compressive strength <300Mpa), such asiron ore. steel slag. phosphate rock, copper ore, silicon ore. limestone. quartz stone. ceramicsand solid materials of comparable hardness Rough and medium crushing operations, such asfine crushing in the middle block of various concentrating plants, fine crushing in the middleblock of limestone in cement plant, etc., with large crushing ratio. low maintenance cost, lowpower consumption and reliable performance.Norking PrincipleThe (Fineliaw crusher is driven by a motor through a V-belt and a pulley to drive the eccentricshaft to move the movable jaw up and down. When the moving jaw rises, the angle between thebracket and the moving jaw becomes larger, so that the movabie jaw is formed close to thefixed jaw. The crushing chamber, at which time the material entering the crushing chamber iscrush’ed and crushed: when the moving jaw descends, the angle between the bracket and themoving jaw becomes smaller, and the moving jaw is separated from the fixed jaw by the actionof the tie rod and the spring. The broken finished material is discharged from the lower mouthof the crushing chamber, so that the continuous rotation of the motor drives the moving jaw toperform periodic operation to crush the material.

PE(X)Series(Fine)Jaw Crusher

| Specification | Inlet size mm) | Feed size oìmi) | Dscharge sze (6e51a3em | Production capacityt/hy | Notor Powe (Kw | Dimensions L×WXH] | Weight (t) |

| PE-400×250 | 400×250 | <210 | 20-60 | 5-20 | 15 | 1450×1315×1296 | 2.8 |

| PE-400×600 | 400×600 | <340 | 40-80 | 16-65 | 30 | 1565×1732×1586 | 5.5 |

| PE-500×750 | 500×750 | <425 | 50-100 | 45-100 | 55 | 1890×1916×1870 | 10.2 |

| PE-600×900 | 600×900 | <500 | 60-120 | 50-120 | 75 | 2305×1840×2298 | 16.5 |

| PE-750×1060 | 750×1060 | <630 | 80-140 | 115-210 | 90 | 2730×2472×2800 | 29 |

| PE-900×1200 | 900×1200 | <750 | 95-165 | 140-260 | 110 | 3335×3182×3025 | 50 |

| PE-1200×1500 | 1200×1500 | <1100 | 110-200 | 300-800 | 160 | 4200×3300×3500 | 95 |

| PE-1500×1800 | 1500×1800 | <1200 | 220-350 | 500-1000 | 315 | 5160×3660×4248 | 128 |

| PEX-250×750 | 750×250 | 210 | 25-60 | 15-35 | 22 | 1380×1750×1540 | 4.9 |

| PEX-250×1000 | 1000×250 | 210 | 25-60 | 16-45 | 30 | 1560×1950×1390 | 6.5 |

| PEX-250×1200 | 1200×250 | 210 | 25-60 | 20-60 | 37 | 2140×1660×1500 | 9,5 |

| PEX-300×1300 | 1300×300 | 260 | 25-90 | 25-90 | 45 | 2720×1950×1600 | 14.7 |

| PEX-500×1500 | 1500×500 | 450 | 25-90 | 30-120 | 75 | 3020×2150×1870 | 18.5 |

| PEX-500×2000 | 2000×500 | 450 | 25-100 | 40-120 | 90 | 3220×2150×1870 | 21.5 |