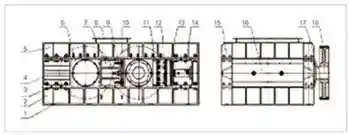

1.Anchor Bolt hole 2.Lower frame 3.Carrier pin 4.Fixed roller bracket 5.Upper frame 6.Bearing Seat 7.Intermediate frame 8.Inlet 9.Screw 10.Adjusting Pad 11.Bearing housing 12.Spring 13.Spring force box 14.Cylinder 15.Locating pin 16.Observation window 17.Main shaft

18.Main wheel pulley

Introduction

This energy saving roller press machine is our company s product which is developed on the basis of leaming and absorbing various advanced technologies at home and abroad.It is suitable for materials compression strength less than 300Mpa,moisture content less than 30%of the hard materials to proceed fine crushing in the primary

operations.Can be widely used in cement,mining,metallurgy,ceramics and other industries.

Energy saving roller press machine is equipped with two rollers.The roller surfaces adopt wielding and hardness alloy circular pin roller surfaces.It is applicable to the materials of which the feed particle size that less than 70mm and the product size3-15mm for fine crushing.Such as cement and aluminum industry pre-crushed cement clinker,limestone and composite materials;iron ore industry broken iron ore,steel slag;ceramic industry broken potassium sodium

feldspar,quartz mining broken quartz stone;bum-free brick factory broken each The ore is made of non-burnt bricks; or a crushing occasion similar to the above.

Working Principle

The energy saving roller press machine adopts the two relatively rotating rolers to produce high compression force (about 150Mpa).Two rollers are arranged in horizon.The powder material on itself weight is compulsorily fed into the gap between two rollers over the rollers continuously and equally.When the material enters into the gnipping area it is gnpped by the roler.With the continuous tuming of the roller,the occupied space of the material is getting less

smaler and gradually compressed and reaches the max value of the formation pressure.

2PGJ Series Energy Saving Roller Press Machine

| No. | Specification | Feed size (mm) | Discharge size (30stabcim | Production capacity(th) | Motor Power (Kw) |

| 1 | 2PGJ-40 | <30 | 3-15 | 20-60 | 30×2 |

| 2 | 2PGJ-60 | <30 | 3-15 | 35-90 | 55×2 |

| 3 | 2PGJ~90 | <30 | 3-15 | 50-140 | 90×2 |

| 4 | 2PGJ-80 | <50 | 3-15 | 30-120 | 75×2 |

| 5 | 2PGJ-110 | <50 | 3-15 | 60-160 | 110×2 |

| 6 | 2PGJ-130 | <50 | 3-15 | 80-260 | 132×2 |

| 7 | 2PGJ-100 | <70 | 3-15 | 50-160 | 90×2 |

| 8 | 2PGJ-150 | <70 | 3-15 | 80-200 | 132×2 |

| 9 | 2PCJ-180 | <70 | 3-15 | 100-300 | 160×2 |