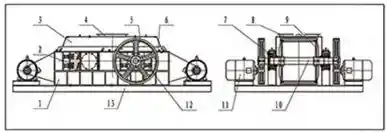

1.Bearing seat 2.Inlet 3.Tightening sleeve 4.Reducer 5.Universal Shaft 6.Motor 7.Reducer Bearing seat 8.Energy storage 9.Hydraulic station

Introduction

2PGY Series Roller Press Machine

is suitable for compression strength less than 300Mpa,humidity less than 35%of the hard and soft materials,primary operations in the medium and fine crushing Can be widely used inmine,chemical

industry,cement,building materials and other industrial sections.The equipment has the characteristics of low maintenance cost,reliable performance,less dust and low noise.

Double raller crusher has two kinds of surfaces according to user needs,oneis flat and another is welding surfaces.

Rat roller surface model is suitable for the following technical requirements:feed size less than 80mm,product size 3-10mm.Such as the use of pebbles,construction waste making sand;mining crushing iron ore,quartz stone;

ceramic industry break raw materials;metalurgical industry crushing coke,quicklime;coking plant finely pulverized etc,or at similar crushing occasions.

Welding roller surface model is suitable for feed size less than 150mm,finished size 5-30mm in crushing operations.It can be used in the pre cnushing of cement clinker in cement industry,Imestone and

composites;CWS industry pre crushing coal iron ore industry pre crushing slag,iron ore,silicon ore;brick factories crushing all kinds of ore to make unbumed brick;power plant crushing coal;or at similar crushing occasions.

Working principle

Double teethed roller crusher is equipped with two high strength wear-resistant alloy rollers.Their relative rotation generates high extrusion pressure which crushes the material.The material is fed into the space between the two rollers,suffered both extrusion and shear force.In the crowd rolling,cutting and grinding,then it is crushed into the required size and then sent by the transport equipment

2PGY Series Roller Press Machine

| No. | Specificatiom | Feed size mm) | Discharge size acstebemmy | Production capacity(t/n) | Motor Power (Kw) |

| 1 | 2PGY-150 | <40 | 4-20 | 120-180 | 250×2 |

| 2 | 2PGY-200 | <40 | 4-20 | 150-240 | 370×2 |

| 3 | 2PGY-260 | <40 | 4-20 | 240-295 | 450×2 |

| 4 | 2PGY-300 | <40 | 4-20 | 290-360 | 550×2 |

| 5 | 2PGY-400 | <40 | 4-20 | 340-500 | 750×2 |

| 6 | 2PGY-500 | <40 | 4-20 | 400-610 | 1000×2 |

| 7 | 2PGY-700 | <40 | 4-20 | 620-750 | 1200×2 |