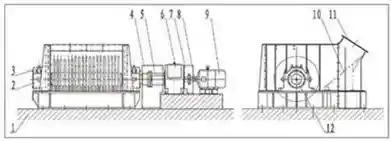

1.Foundation 2.Bearing seat 3.Teethed roll assembly 4.Cross slide coupling guard

5.Cross slide coupling 6.Reducer 7.Pin coupling guard 8.Pin coupling 9.Molor 10.Grid 11.Inlet 12.Water cooling port

Introduction

Single-tooth roller crusher is suitable for medium-hardness (compressive strength <150Mpa).The coarse crushing of solid materials,such as sinter,coal,slag,oil shale,soft ore and other materials. It has the characteristics of large crushing ratio,high temperature resistance,simple structure, reliable performance and low power consumption.Can be used in metallurgy,coal,electric power. chemical,mining and other industries.

Working Principle

The single-tooth roller crusher is a new type of coarse crushing equipment that combines the advantages of the roller crusher and the jaw crusher and utilizes the advantages of the two crushers.

The single-tooth roller crusher is composed of a toothed roller and a fixed sieve plate. The toothed roller is driven by a motor,a reducer and a coupling.The bulk material enters the crushing cavity composed of the toothed roller and the sieve plate from the feeding port,and is subjected to the impact and splitting action of the broken food breaks the material to the required particle size.

In order to ensure the reliability of the single-tooth roller crusher in high temperature

environment,the hollow shaft water circulation cooling method is adopted to control the bearing temperature within a certain range.

PG Series Single-Tooth Roll Crusher

| Sbecification | Feed size | Ddrrge sze | Tocthroleute | Tecthrol | Toothros | Rinbere | Proxlucticn | MotorPoer | Resltcer |

| (mm) | lastebe nm) | camneteimo: | ěngiil(mm) | ros | Sncerowteet | dapacityt | (Kw) | Mokler | |

| PG1100× 1620 | ≤1500× 1000×500 | 150 | 小1100mm | 1620 | 5 | 3 | 120 | 22 | ZS125-11-1 |

| PG1100 × 1860 | ≤1500× 1000×250 | ≤100/≤150 | φ1100mm | 1860 | 7/6 | 3 | 140 | 22 | ZS125-11-1 |

| PG1100 × 1860A | 375000000 | ≤120 | φ1100mm | 1860 | 8 | 3 | 130 | 22 | ZS125-11-1 |

| PG1100× | ≤1500 × 1000×250 | <100 | φ1100mm | 1860 | 10 | 3 | 110 | 30 | ZS125-11-1 |

| PG1500 × 2400 | ≤2000× 1000×300 | ≤200/≤150 | φ1500mm | 2400 | 5/7 | 4 | 200 | 55 | ZS165-9-11 |

| PG1800 × 3240 | ≤3000× 2000×700 | ≤150 | φ1800mm | 3240 | 12 | 3 | 450 | 90 | ZS185-9-11 |