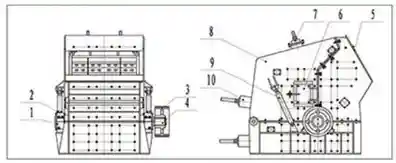

1.Bearing seat 2.Oil cup 3.Pulley 4.Main shaft 5.Inlet 6.Observation

window 7.Rear shelf assembly 8.Rear cover 9.Cylinder 10.Adjustment device

Im(Int)pac(rod)t(u)cc(t)iru(o)s(n)her can be applied in the first and secondary crushing process,dealing with the

materials of which the compression strength is not more than 350Mpa,like

granite,basalt,iron ore,manganese ore,limestone,gold ore,concrete etc.The utility model has the advantages of large crushing ratio,good broken granular shape,compact structure,

reliable performance,long hammer life and convenient maintenance.Therefore,it is widely used in railways,highways,cement,mining,chemical,construction and other industries.

Working Principle

Impact crusher is a crushing machine that uses impact energy to crush materials.the rotors driven by the motor power to rotates with a high speed.When the materials enter the

working area,they will be impacted by the board hammers on the rotor and be thrown onto the impact plate.The materials which spring back from the impact plate will be struck by

the board hammers again until they reach the desired size,after which the materials will fall through the screen plate under the rotor.The crushed materials which meets the required size will be discharged from the outlet.

PF Series Impact Crusher

| No. | Specification | tinlet size (mm | Feed size (m) | Diderge sze dstSenn | Production capatityttrn) | Metx Rsnt (KvN | Weight ( | Dimensions (L*W*E) |

| PF-007 | φ1000×700 | 400×730 | ≤300 | 20 | 30-70 | 45 | 9 | 2330×1660×2300 |

| PF-1010 | φ1000×1050 | 400×1080 | <350 | ≤25 | 50-90 | 55 | 13 | 2370×1700×2390 |

| PF-1210 | φ1250×1050 | 400×1080 | ≤350 | ≤30 | 70-130 | 110 | 16 | 2680×2160×2800 |

| PF-1214 | φ1250×1400 | 400×1430 | ≤350 | ≤40 | 100-180 | 132 | 20 | 2650×2460×2800 |

| PF-1315 | φ1320×1500 | 860×1520 | ≤500 | 50 | 130-250 | 220 | 24 | 3180×2720×2620 |

| PF-1520 | φ1500×2000 | 830×2040 | ≤700 | ≤72 | 300-550 | 440 | 38 | 3959×3564×3300 |