Introduction

PPC type air box pulse bag type dust collector is a new type of dust colector developed and proclucedby our company to absorb the advantages of various foreign dust collectors.This senes of products has dozens of speciications,which are dvided into several boxes according tö the size of the dust collector.There are four kinds of bags in each room:32. 64.96,and 128 bags.The length of the fiter bag is 2.450 mm and 3060 mm.The amount of flue gas treated is 3000-3000000m3/h,the concentration of flue gas dust is ≤1200g/Nm3,the dust removal efficiency can reach above 99.9%,and the dust concentration of the purified gas is less than 50g/Nm3,which can meet the requirements of cement,electric power,metalurgy,chemical industry,etc.A variety of flue gas dust treatment needs are required in the

industry.

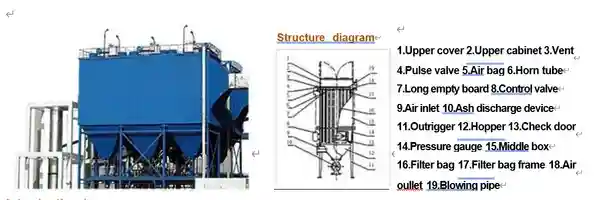

Working PrincipleThe dusty gas enters the ash bucket from the air inlet of this equipment Partof the coarser dust particles due to inertialcollision,Natural sedimentation and other reasons fall into the ash here.Most of the dust particles nise to the bagchamber with the airflow.After fitering through the fiter bag,the dust particles are retained on the outer surface of thefiter bag.The purified gas enters the box from the inside of the fiter bag,and then the valve plate hole and the air outletport are arranged.Into the atmosphere.Achieve the purpose of dust removal.As the filtration process continues,thedust on the outer surface of the fiter bag gradually increases,and the running resistance of the dust collector graduallyincreases When the resistance reaches a preset value,the cleaning controllersends a signal.First control the poppetvalve to close the valve plate hole.In arder to cut off the fitered airflow,stop the fltration process,and then the batterypulse valve opens,injecting compressed air into the tank in a very short time.The compressed air expands rapidly in thetank and flows into the interior of the filter bag,causing deformation and vbration of the fiter bag,In accition,the duston the outer surface of the fiter bag is removed into the ash hopper.After the cleaning is completed.The poppet valveopens again The dust collector enters the filtering working state,and the cleaning control has two control modes timingand constant resistance.

PPC Series Air Box Pulse Bag Filter

| Pemmet/Specificafon | Handling an wdlumie () | Totalfltraticn areə | lteing vind speedi/min) | Total number ffiter 53g | 8ody esstance (ca | Ursestand gatxe pressure(c3 | ha:dJst oncen:a!!an gm | onxenttgcn ms心 | wam mncro sze |

| PPC324 | 8900 | 128 | 1-1.8 | 128 | 1470- 1770 | 5000 | <1000 | ≤50 | 3829×2882×7559 |

| PPC32-5 | 11160 | 160 | 160 | 4496×2882×8025 | |||||

| PPC32-6 | 13390 | 192 | 192 | 5163×2882×8600 | |||||

| PPC64-4 | 17800 | 256 | 256 | 6137×2559×7590 | |||||

| PPC61-5 | 22300 | 320 | 320 | 7356×2559×7590 | |||||

| PPC64-6 | 26700 | 384 | 384 | 9119×2559×7590 | |||||

| PPC64-7 | 31200 | 448 | 448 | 10388×2559×7590 | |||||

| PPC64-8 | 35700 | 512 | 512 | 11557×2559×7590 | |||||

| PPC96-4 | 26800 | 384 | 384 | 6139×3416×8413 | |||||

| PPC96 -5 | 33400 | 480 | 480 | 7356×3416×8413 | |||||

| PPC96-6 | 40100 | 576 | 576 | 9119×3416×8413 | |||||

| PPC96-7 | 46800 | 672 | 672 | 10388×3416×8413 | |||||

| PPC96-8 | 53510 | 768 | 768 | 10557×3416×8413 | |||||

| PPC96-9 | 60100 | 864 | 864 | 12776×3416×8413 | |||||

| PPC128-6 | 67300 | 768 | 768 | 8525×3810×8300 | |||||

| PPC128-9 | 100900 | 1152 | 1152 | 12827×3810×8300 | |||||

| PPC128-10 | 121000 | 1280 | 1280 | 14046×3810×8300 |